Warehouse Management

Optimizes warehouse operations and physical inventory management.

Introduction

The warehouse module in inventory management system allows for effective management of physical storage of goods within a business. It facilitates organization and tracking of inventory across different or within warehouse locations, managing the movement of items between bins, staging areas and loading bay.

This includes process of receiving goods from vendors, storing them in assigned bins and a staging area, and fulfilling orders by picking and packing items for shipment. It also allows for minor re-packaging processes such as applying stickers, preparing for compliance inspections, and more.

With this module, businesses can optimize their warehouse operations for efficient storage, tracking, and retrieval of inventory.

Features

Warehouse Explorer

This feature allows users to view an overview of the warehouse storage, including the location and quantity of inventory within the warehouse. It provides a visual representation of the warehouse layout, including the shelves, bins, and staging areas.

Put Away

This feature allows users to assign storage bins to a list of inventory items. Users can select the items to be stored and the specific bin or location where they should be placed.

Pick Order

This feature generates a document that lists the inventory items to be picked from a specific bin or location. It includes the item details, quantity, and bin location, making it easy for warehouse workers to locate and retrieve the items needed.

Pack Order

This feature generates a list of inventory items and instructions on how they should be packed into specific loading sizes, such as pallets, cartons, and TEU containers. It helps warehouse workers to efficiently and accurately prepare items for shipment.

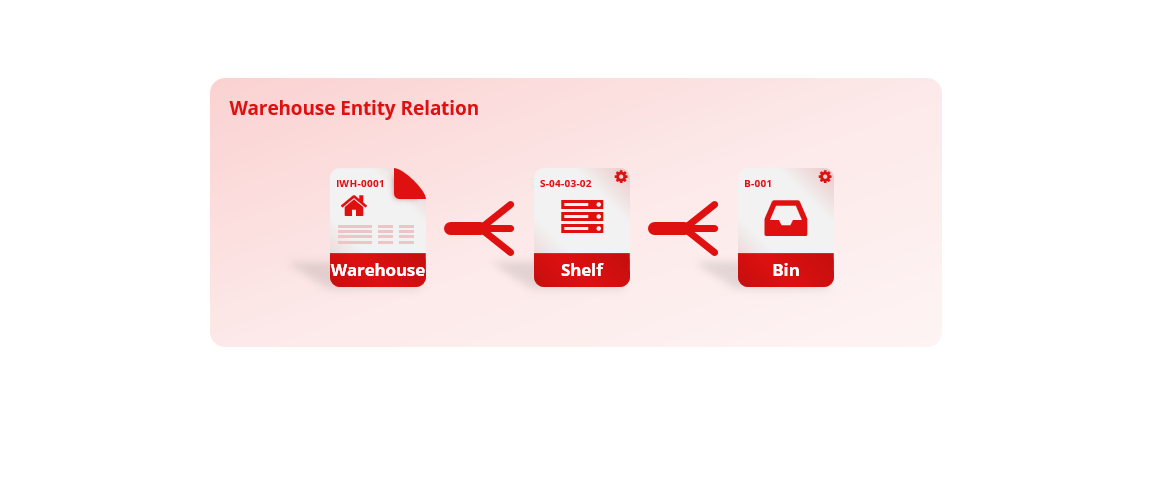

Warehouse

This feature represents a physical location where all warehouse operations and inventory are processed. It includes shelves, bins, and staging areas, which are used to organize and store inventory.

Shelf

This feature represents an organizational structure within a warehouse, used to organize bins and provide an addressing system for locating each bin.

Bin

This feature represents a single, addressable location within a warehouse where a specific type of inventory is stored. Bins are used to store items that share the same inventory group and production batch.

Lot

This feature represents a specific grouping of items within a warehouse, used for tracking inventory that has a specific characteristic in common, such as a manufacturing date, expiration date, or batch number.

Lot numbers can be automatically generated based on set criteria and it can be used to manage expiry dates and FIFO method.

Processes

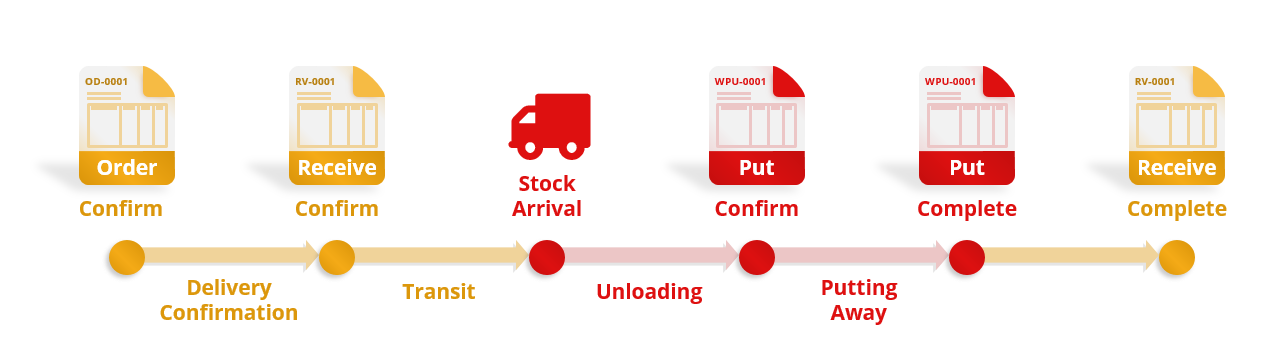

Receiving Physical Goods

The process of receiving goods begins with confirming the purchase receive document, which contains the expected delivery date. Once the goods have been delivered and unloaded from the truck, they are placed in a staging area for sorting and organizing.

Next, the inventory is allocated to specific bins based on their inventory group and assigned lot number. This ensures that items with similar characteristics are stored together, making it easier to manage and retrieve inventories.

Finally, the inventory is moved to its designated bin through a process called “put away”, which is assigned a specific location within the warehouse for each item. Throughout the process, inventory quantities are reflected in the system.

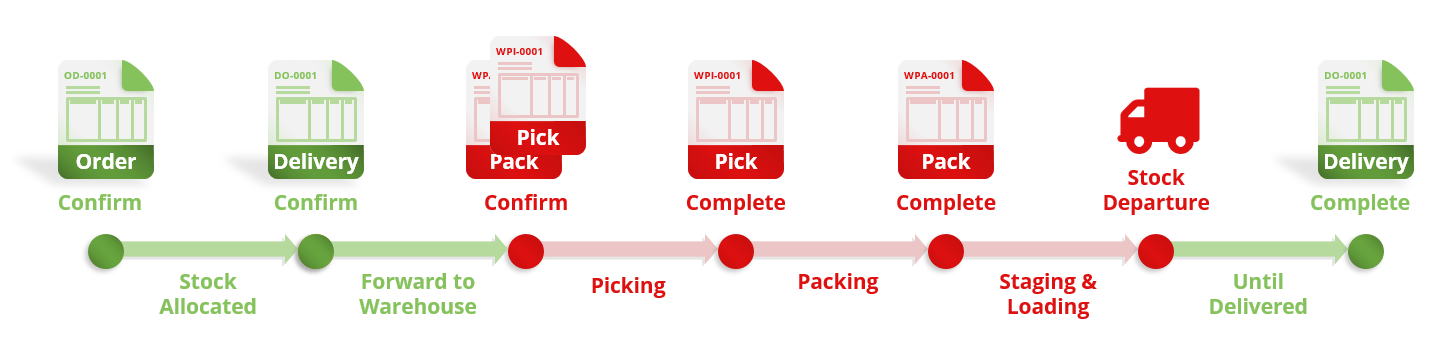

Shipping out Orders

The process of shipping goods begins with the creation of a sales delivery order. This document contains information such as the customer’s shipping address and the items that they have ordered.

Once the sales delivery order is confirmed, the inventory is picked and packed inside the warehouse according to the instructions in the order. The items are then moved to the staging area where they are loaded onto the courier truck for delivery.

Learn more

Tours

- Bookkeeping & Automation

- Tips to do thing and that

Tutorials

- Bookkeeping & Automation

- Tips to do thing and that